WoR Rotary Kiln Refractory Brick Installation Bricking Machine

Rotary kiln bricking machine

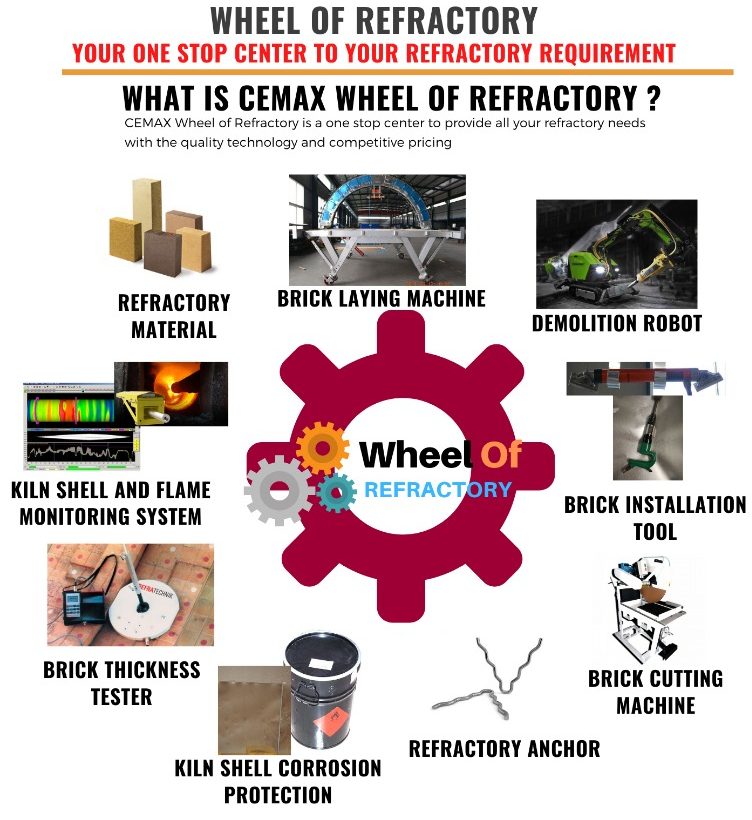

CEMAX World-of-Refractory Bricking Machine offers a combination of reliable, efficient, safer and quicker refractory installation for rotary kiln. This makes part of the circle of refractory lining solutions.

CEMAX World-of-Refractory Bricking Machine offers a combination of reliable, efficient, safer and quicker refractory installation for rotary kiln. This makes part of the circle of refractory lining solutions.

The bricking machine is customized for rotary kilns of diameter 2.80 to 7.50 meters.

These bricking machines are suitable for rotary kilns in cement works, incinerators, and pulp paper mills.

What is the features and advantages of the brick laying machine?

- The adjustable dual arch structure is fitted for all sizes of bricks.

- The working platform can be adjusted as large as for kiln of 5.20 meters diameter.

- Two rows of bricks can be laid together at the same time to speed up the bricks laying. The user-friendly design of arch track can reduce the masons’ tiredness and to increase safety and efficiency.

- The three-way master valve on the arch can control the cylinders independently, which could also be controlled simultaneously without re-start.

- Light weight and strong load-bearing; easy and quick adjustment.

- Being equipped with laser locator for the bricks; easier and more reliable for masonry.

World-of-Refractory supporting equipment of brick lining installation

Kiln Access

- Ramp – to provide access for people and equipment from the kiln floor into the kiln; customized design for different kiln design; and lightweight but strong.

- Safety Inspection Cage – to provide safety from falling coating for brick inspection during stoppage.

Debris Removal

- Fitting Bucket – to fit onto forklift for removal of used bricks and debris after taken down from kiln shell.

Brick Transfer

- Hydraulic Belt Conveyor – to convey bricks from kiln floor into the kiln; suitable for small kiln which could not provide access by forklift.

- Brick Rail Track – to provide passage for bricks to go underneath bricking machine.

- Bedding Cart – to allow masons to work efficiently while laying bedding bricks.

Installation

- Suspended Platform – platform for vertical working area such as pre-heater cyclone, vertical lime kiln, and BOF process furnace

- Shim Driver – pneumatic tool to hack shim plate into bricks, rather than using wooden hammer which is not efficient

- Refractory Jack – pneumatic tool to jack and tighten the key bricks

- Brick Cutting Machine

- Castable Anchor

- Brick Thickness Tester

- Sacrificing Sheet

Engineering Services

- Hot Kiln Alignment

- Kiln Shell Replacement

- Air Blaster

Where to find us?

Australia, Bangladesh, Brunei, Cambodia, Canada, China, France, Germany, Hong Kong, India, Indonesia, Italy, Japan, Kazakhstan, Laos, Macau, Malaysia, Mexico, Myanmar, Nepal, New Zealand, North Korea, Pakistan, Papua New Guinea, Philippines, Singapore, South Korea, Sri Lanka, Taiwan, Thailand, United Arab Emirates, United Kingdom, United States of America, Vietnam

Dear Mr/Ms,

One of our customer here in Sumatra is intending to invest a Rotary Kiln Bricking Machine.

We would like to offer a business cooperation with your prestigous company for this project. If you are interested, please spend sometimes to Sumatra for a presentation.

Best Regards,

Rio Handevis

Mobile : +62 853 75051 038

Product Request: Brick Laying Machine

Kiln dia: 4.37 Meters

Company: Dalmia Cement (Bharat) ltd

Thank you for evaluating our proposal.