Concentrate and Suppress Dust of Free Flow Granular Materials

Free Flow Granular Materials

Do you find difficulty to handle free flowing granular materials such as wheat, grain, feed pellet, wood pellet, sand, gravel, fertilizers, chemical compounds, and the list goes on?

The Dust Suppression Solution

How Dust Suppression Works

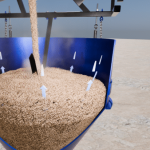

The DustCone hopper discharge system is strategically mounted beneath the material feed point and suspended over the discharge interface to optimize flow dynamics.

As material fills the hopper, the increasing back pressure extends the system’s spring mechanism, gradually opening the flow control gap for a smooth and controlled release.

This engineered motion compresses the product into a dense, solid column while forcing out entrained air – right before discharge. The result? A virtually dust-free transfer, with cleaner operation and improved loading efficiency across a wide range of applications.

The system produces a compact, cohesive stream of material that maintains its integrity even from significant drop heights. During transfer, any airborne dust is captured within the moving column, resulting in minimal visible emissions at the point of impact.

By removing excess air during discharge, the system also reduces material segregation – delivering a cleaner, more consistent load every time.

Benefits and Features for Customers

1. No power consumption – Reduce energy and installation costs.

2. No internal moving parts – Reduce maintenance costs.

3. Reduced product degradation – Increase returns.

4. Minimized dust

- Lessen the need for dust collecting machineries.

- Reduce cleaning costs.

- Improve health and safety for employees.

- Dust explosion risk mitigation.

- Faster and cleaner loading.

- Reduce neighbourhood pollution.

5. Improved loading – Improve angle of repose, which increase storage capacity.

6. More product in the storage container – Less air entrapment, which enable increase loads and returns.

Applications