SUPERTHERM Coal Additive for Fossil Fuel Coal Fired Burning

Coal additive for coal burning or coal combustion is a technology interested by many coal fired industries.

It is an unique solution to energy efficiency for cost saving, and environmental sustainability for global warming.

S2KR has been recognized in power, steel, cement, textile, pulp and other sectors using thermal coal as fuel source.

This innovative product is developed in research collaboration with the Indian Institute of Technology, Kanpur.

Why SK2R for coal burning

- Increase energy price

- Limited availability of conventional raw energy source

- It provides better and more efficient combustion process

Advantages of SK2R for coal fired power plants

- Enhances thermal output on the combustion system making it energy efficient

- Reduce emission of COx/NOx/SOx gases for global warming

- Economical and saves coal consumption

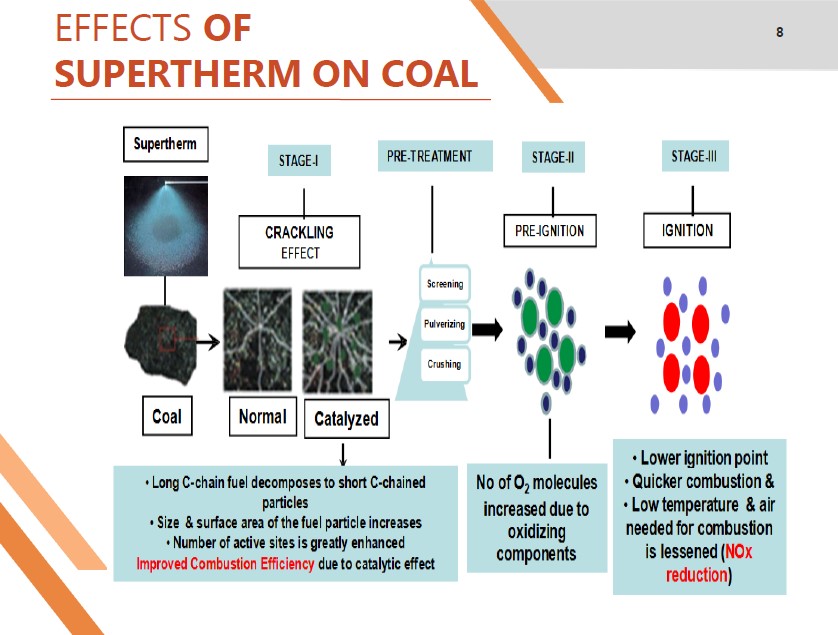

Reaction mechanism of S2KR

Complete combustion can help in saving 10 to 15% of fossil fuel costs and little quantity of H2O and alumina can change the quality of coal instantly to improve boiler or kiln performance and upsetting conditions instantly

CO2+2H2O=CH4+2O2(METHATIONREACTION)

Reaction of alumina particles present in coal ash and hot water vapor also invites ash fusion in boiler / cement kilns after coming close to each other

2Al+3H2O=Al2O3+3H2