Hot kiln alignment service package

GEOSERVEX’s rotary kiln services include troubleshooting and root cause analysis, comprehensive hot kiln alignment, in-situ grinding of tyres, support rollers and thrust rollers, installation, maintenance, repair work, technical guidance and support on all rotary kiln equipment suppliers.

HOT KILN ALIGNMENT MAINTENANCE & INSPECTION ROGRAMMES

Our maintenance inspection programme has been designed to help clients adopt a proactive approach to rotary kiln maintenance. Direct benefits of our maintenance and inspection programmes include:

- Compilation of a comprehensive history of wear rates for mechanical components

- Reduced unplanned stoppages

- Achievement of maximum plant availability thereby increasing production and reducing operating costs

- Reduced wear rates achieved due to rotary kilns being correctly aligned on a regular basis

- Installation & Repair

- Efficient planning for programmed shutdowns

- Confident budget planning for replacement of high cost items such as girth gears, pinions, tyres and trunnion rollers

SURVEY PROCEDURE HOT KILN ALIGNMENT

Comprehensive hot kiln alignment ensures that rotary kilns are able to achieve maximum efficiency throughout their service lives and help customers avoid unforeseen breakdowns.

Almost all problems associated with rotary kilns can be attributed to misalignment. Although the current trend is towards ‘soft’ non-contact measurements taken from areas outside the hot air envelope along the vessel, there are inherent problems associated with this technique, such as:

- Temperature front refraction

- Variable light conditions

- Oblique angles

- Unbalanced geometric networks

- Limitations of electronics in harsh environments

TECHNOLOGY

CEMAX Engineering Malaysia represents global leading specialist GEOSERVEX from Poland in providing measurements and analyses of rotary machine deformations and measurements.

GEOSERVEX since its inception in 1983 is the world’s first developed and implemented technology of kiln alignment in dynamic conditions (during normal operation), termed “Hot Kiln Alignment” specialises in developing, implementing and realizing unusual and highly precise geodetic measurements. The method was patented and used in 42 countries around the world.

Our specialised high precision survey system is a coordinate system and a set of reference points, used to locate coordinates. The most specialized field of our activity are measurements and analyses of rotary machine deformations and measurements of ground displacements of industrial structures, constructions and equipment

HOT KILN ALIGNMENT SERVICES PACKAGE

Our company’s hot-kiln alignment services offering results in the provision of the following:

- Current rotary kiln alignment status

- Condition of the tyres and trunnion rollers including tyre chairs and tyre stops

- Tyre and trunnion roller running face profiles

- Measurement of roller parameters

- Trunnion roller inclinations

- Kiln adjustment programme and schedule

- Kiln thrust and mechanical balance

- Mechanical balance of the hydraulic system pressure

- Drive-mesh inspection

- Tyre and girth gear wobbling

- Girth-gear radial run-out

- Accurate measurement of kiln-shell profile

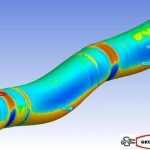

- Kiln-shell 3D model

- Mechanical and temperature crank formation

- Tyre migration and shell-ovality tests

- Analysis of loads, pressures and stresses

- Stiffness matrix

- Advanced kiln modelling

- Comprehensive test of kiln mechanical parameters

All of the above information is supplied, along with alignment adjustment recommendations, in a comprehensive report together with a series of drawings which can be supplied in either hard copy or electronically. Included in the package is a comprehensive mechanical condition report with recommendations for the repair or improvement of the relevant plant items.